Printing methods

There are a number of different printing methods that are all good in different ways. The choice of method depends, among other things, on what the product looks like, what the material is and what results you want. How do you know which labelling method is right for the product? You never need to worry about that. We’ll take care of everything.

Pad printing machines

Pad printing machines expand the limits of what is possible. This printing method involves an elastic silicone pad that transfers ink from a printing block onto the substrate that will be labelled. We manufacture all our own consumables which gives us a unique opportunity to adapt the method to your specific needs. This particular printing process provides unbeatable results when it comes to decorating and labelling plastic, metal, glass, lacquered surfaces and wood, and much more, all at a minimal cost per print.

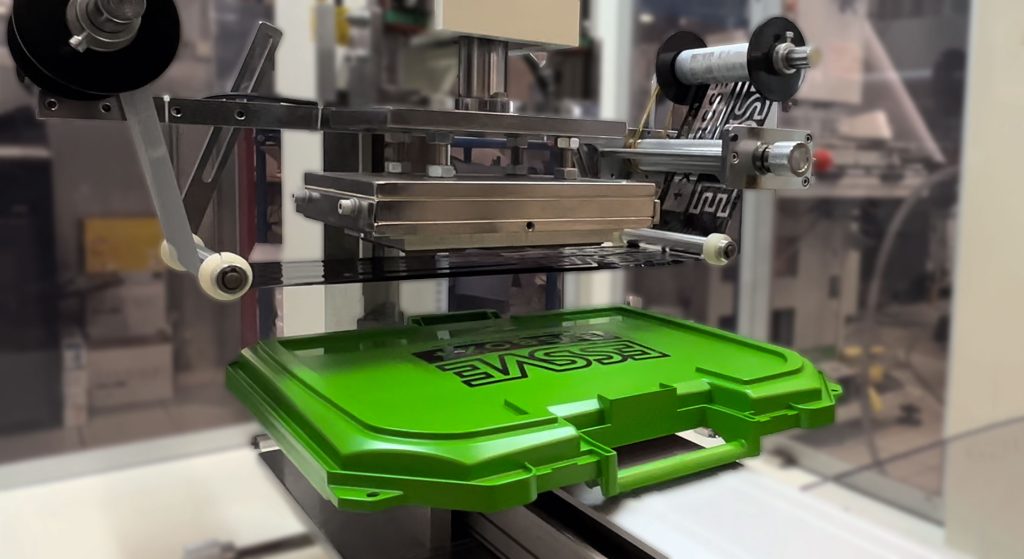

Screen printing machines

The printing method is based on using a squeegee to squeeze ink through a fine-mesh cloth onto the product that will be labelled. Screen printing machines provides a simple, but very effective method, especially on flat and round surfaces. It has a short drying time, superior durability and makes for results of the highest quality. This versatile printing technique also allows for detailed end result on textiles, plastics and metals, among other things.

Hot stamping machines

Hot stamping is a printing method where you place a colour foil between a heated cliché plate and the product to be printed. The hot cliché plate is then pressed against the foil, releasing its colour layer, which is transferred to the material by heat and pressure. It is possible to hot stamp most materials, except for metal and glass, but the most common is plastic.

DTF printing machine

DTF – Direct to Film means printing with water-based pigment inks on polyethylene terephthalate (PET) film. After curing, the image can be transferred to a garment using a standard heat press. The DTF process requires no pretreatment and can be applied to many types of fiber compositions. You get a vivid print with a wide color gamut and the quality of the print is exceptional as lines, small fonts and fine details are printed accurately.

Laser marking machines

Laser marking involves removing material with a laser beam in order to create the desired effect. This can give a tone-on-tone feel, which results in an elegant and exclusive finish. It can also give the opposite effect of an obviously lasered result. This marking method is suitable for a variety of materials, such as metal, plastic, wood or glass products, and is ideal for marking batch numbers, serial numbers, QR codes and barcodes.

Digital printing machines

Digital printing machines enable quick and personalised printing in many different colours and tones. Because the print is entirely digital, no intermediate steps are needed, such as films and printing plates. This also enables adjustments late into the printing process, and you can personalise each individual product with unique text and images, for instance, without slowing down production. Digital printing is mainly used for smaller editions and is a good complement to other printing methods.